|

|

Liu Bao tea processing techniques have come a long way over the years, and have traveled an interesting course in their development. Despite this, there is a lack of research into this topic, and materials are somewhat scarce. So, in this article, I have gathered together some knowledge of Liu Bao processing techniques, recorded from the memories of the older generations of local Chajin from Liu Bao itself, so that we might delve into the evolution of this tea and the factors behind it.

Firstly, a brief summary of Liu Bao tea's earliest roots. One school of academic opinion that's considered fairly authoritative describes the evolution of tea styles as follows: In the Tang Dynasty, tea leaves took the form of steamed green tea cakes. At this time, the well-known tea saint Lu Yu classified tea into four kinds, according to the brewing method: "coarse" tea, loose-leaf tea, powdered tea (matcha) and tea cakes. Then, during the Song Dynasty, steamed green tea cakes evolved into steamed green loose-leaf tea. The Song Dynasty saw a proliferation of different types of tribute tea, from flat-leafed "tablet-shaped" tea (片茶) to the foamy white la mian (臘面) tea. Loose-leaf tea was also a product of the Song Dynasty. By the time of the Yuan Dynasty, tea cakes had gradually been phased out, and looseleaf varieties developed even more. The Song and Yuan dynasties were a golden age for the tea industry in southern China. It's said that in the Liu Bao region (which was not yet named Liu Bao at the time), tea production methods also changed, coming to resemble the popular steamed green tea methods. The older and coarser leaves were used to make the tea cakes that were popular at the time (one tea producer in Guangxi, Xiuren, during the Song Dynasty was known for tea cakes). The young shoots were used to make green tea according to conventional methods. By the Ming Dynasty, tea leaves began to shift away from pure green tea production methods, and the first "fermentation" techniques began to emerge. Throughout their long-time experience of harvesting and processing tea, people noticed that fermented tea had a unique character, and that different fermentation methods created different styles of tea; thus red, yellow and black teas were created. Liu Bao tea (六堡茶), made using early black tea processing methods, is likely to have originated during this era at the earliest.

In the early Song Dynasty, a book entitled Records of a Peaceful World (太平寰宇記) was published in 987 BCE, the fourth year of the Yongxi era during the reign of the Emperor Taizong (revised edition by Wang Wenchu, Zhonghua Book Company, 2007). This book details the geography, scenery and local products of various regions; the 164th entry on local products from the then-prefecture of Fengzhou in southern China contains a reference to "Spring Purple Bamboo Shoot Tea" and "Summer Purple Bamboo Shoot Tea." The name Purple Bamboo Shoot or zisun (紫笋) comes from a line in Lu Yu's Tea Sutra (Cha Jing, 茶經) that reads: "Purple is superior; bamboo shoots are superior." The most famous of these teas was Guzhu Purple Bamboo Shoot tea, which was offered to the imperial household as a tribute tea for around 80 years during the Tang Dynasty. In the year 843, during the Huichang era, around 10 metric tons of Purple Bamboo Shoot tea were given as tribute; the royal household erected stone tablets engraved with the volume of the tribute. From the Tang Dynasty, and throughout the Song and Yuan through to the late Ming, this tea was given as a royal tribute tea for a total of 876 years. Among China's tribute teas, Guzhu Purple Bamboo Shoot tea can claim a lot of superlatives: It's the tribute tea with the longest history, was produced on the largest scale and in the greatest volume, and was of the finest quality. Guzhu Mountain Purple Bamboo Shoot tea has a very unique characteristic that earned it its name: the shoots are purplish and resemble bamboo shoots in shape. So, the Spring and Summer Purple Bamboo Shoot teas that we saw listed as local products of Fengzhou in the early Song Dynasty likely also shared similar characteristics and would have been of fine quality.

Records indicate that the two former counties of Fengchuan and Kaijian covered roughly the same territory as today's Fengkai County in Guangdong. So, the Fengzhou referred to in the Song Dynasty records is likely the area of modern-day Fengkai. Some time ago, in hopes of verifying this, I traveled to modern-day Fengkai County in Guangdong, along with some Chajin from Liu Bao, to visit some tea mountains and plantations in the area. These included the Fengkai Dazhou Tea Plantation, the Hongfeng Tea Plantation (out of operation since the 1980s), the Qilin Tea Plantation and the Xinghua Baima Tea Plantation. During our visit, we noticed that the original Liu Bao tea plant varietal only grew in the areas between the Liu Bao and the He rivers ancient tea boat route, including places such as Libu, Mushuang and Dazhou. On the other hand, tea mountains that were further from the river, such as the Baima Plantation, only had local tea plant varieties growing there, and none of the Liu Bao varietal. The tea plants growing in Fengkai today can be broadly categorized into two varieties. The first is the tree-shaped large-leaf variety, of which the oldest trees are around 60 - 70 years old. These plants do not display purple shoots. The second variety is markedly different from those growing on the Baima tea mountains - this is the bush-shaped Liu Bao tea plant variety, which grows along the old tea boat route. Introduced more recently, these trees tend to be on the younger side and are generally no older than forty years or so.

At the Qilin Tea Plantation, the elderly Chajin told us that there wasn't anywhere nearby producing tea in large quantities, so the tea they produced was supplied to the neighboring areas. When they were young, they most often drank Liu Bao tea, and they don't remember their elders ever having mentioned other tea producers in the region. These days, in Fengkai's tea plantations, the Liu Bao tea plant variety is referred to as cha'er (茶儿). During the planned economy era in the 1960s and 1970s, these plants were introduced from Liu Bao to Guangxi and cultivated locally to stimulate growth in the tea industry. From observing the tea mountain plantations, we noticed that the native large-leaf varietals did not have purple shoots, nor did the tea from Baima. As for the more recently introduced Liu Bao cha'er varietals, there were also relatively few purple-shoot variants among them; this is likely due to the local soil conditions and micro-climate. The local manufacturing techniques used for this tea also differ significantly from those used in the Liu Bao tea region. Evidently, these Liu Bao arietals were also introduced to other parts of Guangdong in modern times, such as Huaji, Yu'nan and Deqing counties, but purple or red shoots are also scarce in these plantations.

From ancient times, the tea grown in Wu Bao and Liu Bao (literally "Five Castles" and "Six Castles") in Cangwu County, Guangxi, was transported to what is now Fengkai along the Xijiang River, since the land routes were mountainous and difficult to travel. This route became known as the "Old Tea Boat Road," and supplied tea to the inhabitants of places such as Libu, Fengzhou in Guangdong, Yu'nan, Zhaoqing and Deqing. Moreover, the original Liu Bao varietal tea plants grown in Siliu, Buyi and Heishi display a greater proportion of red and purple shoots. So, this does indicate that the Spring and Summer Purple Bamboo Shoot tea referred to in the Song Dynasty Records of a Peaceful World were likely grown in the Liu Bao region and transported down the river to Fengzhou. From the fact that the locals began calling this local tea after the well-known Guzhu Mountain Purple Bamboo Shoot tribute tea that it resembled, we can surmise that it was of excellent quality.

Although steamed green tea cakes made with coarse leaves were common in the Song Dynasty, there are also records of another type of tea that was made with quite different techniques. One such record appears in a poem by Zheng Gangzhong (鄭剛中), a famous poet and official who opposed the Jin Dynasty. One of his poems, written in a traditional structure with seven-syllable lines, is prefaced by the following: "I am very fond of tea. There is a rare and excellent variety found in Fengzhou, with a unique bitterness and astringency similar to low-grade Xiuren tea, of which I drink two cups a day." The poem itself evokes the image of the poet sitting down to a humble meal and a simple cup of tea. The descriptions of the tea in this poem and its preface merit further research, as they offer us an insight into the characteristics and manufacturing techniques of Liu Bao tea during this period - not to mention inspiration.

Another record can be found in a work by Southern Song geographer Zhou Qufei (周去非), Questions from Beyond the Mountains, in the section on "Tea" in the "Food" chapter: "The tea produced in Xiuren County in Jingjiang Prefecture is made into rectangular tea bricks by the locals. The finest examples are two-inch squares and quite thick, bearing the characters "Offered to the Immortals" (供神仙, gong shen xian). The second best are five- to sixinch squares and are quite thin; while the humblest are large, coarse and thin. The Xiuren name is very well known. When brewed and drunk, the liquor is dark in color and heavy in flavor, and can relieve headaches." The Xiuren (修仁) tea referred to here is a wellknown Song Dynasty tea, produced in Xiuren Village in Lipu County, in the Guilin City Prefecture. So, when Zheng Gangzhong likened the tea he drank to "low-grade Xiuren tea," this suggests that the tea in question was made with coarse, older leaves, was of a lower quality, and was compressed into thin cakes, similar in appearance to less-refined Xiuren tea. What's more, take a look at this description: coarse, older leaves compressed into tea cakes, that produce bitter, astringent tea and take on a dark color after aging - is this not an exact description of the old Liu Bao tea cakes that we know today? From the Tang and Song dynasties, Liu Bao tea was made by steaming to halt oxidation (a process known as "kill-green"), then compressing the tea into cakes. Because of the high concentration of tea polyphenols in Liu Bao tea plants and the high water content during steaming, Liu Bao tea cakes turn a dark blackish-brown color after being stored for a relatively short period. Thus, it takes on the qualities of being "dark in color and heavy in flavor," a unique characteristic of Liu Bao that sets it apart from other teas.

Even today, in the homes of local Liu Bao people, one occasionally comes across this kind of tea cake made with old, coarse leaves, stored by hanging them up in front of the stove. The words of Zheng Gangzhong offer an interesting clue: he describes the tea as "a rare and excellent variety found in Fengzhou." Could we, then, interpret this to mean that the tea was not produced in Fengzhou itself, but rather, found in a market, after a lengthy search? After all, if the tea was locally produced, it was unlikely to be "rare" or hard to find. This evidence supports the theory that the tea in Fengzhou during this period was indeed grown in the Liu Bao region and transported along the river, to be sold in Fengzhou and the surrounding areas.

Loose-leaf tea appeared in the Yuan Dynasty, and it gradually became popular with tea makers throughout the Yuan and Ming dynasties, especially in the south of China. The Liu Bao region was no exception. From the beginning of the Ming Dynasty through to the Qing, it gradually became accepted practice for China's various tea-producing regions to make tea according to their own methods, building on the intrinsic qualities of the local leaf and giving rise to a proliferation of unique

styles of tea. From the Ming and Qing onwards, the process of tea making has been based on traditional methods, handed down through the generations. Generally speaking, the tea growers did the work of harvesting and initial processing (kill-green and drying), before selling the tea to merchants, to be transported to various destinations. As the scale of Liu Bao production increased, tea merchants from the local areas or from Guangdong set up facilities in Liu Bao to collect and distribute the tea. During this period, young Liu Bao tea, with its strong, bitter and astringent qualities, came to enjoy a certain popularity. Tea from the Liu Bao tea plant varietal is characterized by its very high tea polyphenol content, its rich quality, its strong flavor and its bitter astringency when the tea is young. But, after several years of aging, the bitterness and astringency mellow out, giving way to a smooth, rich, red-colored tea that is highly esteemed by many drinkers. But how could a tea merchant, who is running a business and needs to maintain a high turnover of goods, possibly wait eight or ten years to sell their tea? To address this need, Liu Bao production methods had to adapt.

One of Liu Bao's elderly tea growers, Li Xuqiu (李旭秋), now in his nineties, recalls that when he was eight years old, his grandmother recounted that in her youth, some of the locally produced Liu Bao tea was sent to Guangzhou for further processing before being exported to places such as Hong Kong, Macau and Southeast Asia. (To estimate from both their ages, this would have been around the 1880s, during the Yuan Dynasty.) But from Li Xuqiu's own earliest memories, the entire Liu Bao manufacturing process was already completed locally from start to finish, with only the final packaging happening in Guangzhou before shipping the tea off for sale.

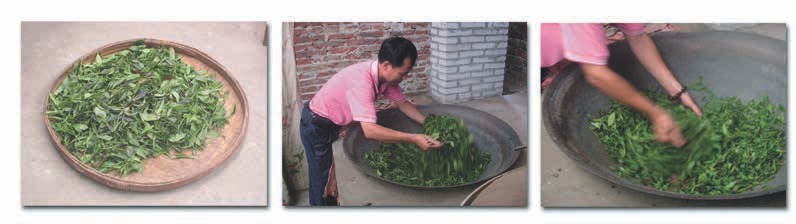

The kill-green step in Liu Bao tea processing was carried out to halt oxidation according to traditional methods, and involves immersing the leaves in boiling water, steaming and pan-firing. This is done at relatively low temperatures, to prepare the tea for the "post-fermentation" process that will follow later. The older, seasoned tea farmers would turn the leaves over in the wok using their hands, in order to get a feel for the temperature and adjust it accordingly. There are several different kill-green techniques in traditional Liu Bao processing. Some special styles of tea, such as Lao Cha Po ("Grandma Tea"), with its old, thick leaves, are not suited to other kill-green methods, so the traditional techniques of immersing in water (lao shui, 撈水) and steaming (zheng qi, 蒸汽) are still used today.

The details of Liu Bao manufacturing in its early days are recorded in A Brief History of Guangxi's Local Products, edited by Wu Zunren (吳尊任) and published in 1937: "During the daytime, the leaves are picked and put in a basket. At nightfall, the leaves are fired in a cauldron until they are very soft; when moisture becomes visible and the leaves begin to stick together, they are taken out. Before the leaves become too cold, they are kneaded with an implement and rolled until they shrink into small, thin shapes and are ready to be used." This record basically describes the kill-green (sha qing, 殺青), rolling (rou nian, 揉拈) and drying steps. In this case, the kill-green step is achieved through pan-firing. There's also another record, believed to come from Guangxi University's weekly journal in 1930, that describes the art of Liu Bao manufacturing at that time: "Each tea bud is picked along with three to five leaves. The initial processing method is as follows: After picking, the leaves are immersed in boiling water, until they are soft and flexible. After about five minutes, they are put in a basket and compressed by trampling with the feet, until the leaves are sufficiently rolled up. Then, the leaves are dried by roasting over a fire. Once dry, they are steamed until soft, then put into baskets ready for sale." This process of immersing leaves in boiling water is presumably the aforementioned lao shui (撈水) kill-green method, seldom used in later times. This old-style lao shui method of boiling the leaves is still used in Liu Bao's tea villages, though; these days, it is mostly used for Lao Cha Po ("Grandma Tea") and other varieties made with coarse, older leaves.

According to the recollections of the region's elderly Chajin, when production volumes were high, the workshops struggled to keep up with demand using traditional techniques, so they began to use the lao shui killgreen method for older leaves. Later, however, steaming became more common as a kill-green method. In 1957, the Guangxi Province Supply and Marketing Cooperative released a publication entitled Tea Picking and Processing Methods, with a section on Liu Bao tea that contains the following excerpt: "Some tea farmers...pack the raw leaves into a handle-less basket or sieve and put the basket inside a pot of boiling water, then place a lid on the pot to steam the leaves... Some tea farmers will place around twenty-five to thirty kilograms of raw leaves inside a wooden steamer basket to steam." So, we can see that in the 1950s, the traditional method of steaming to achieve kill-green was still prevalent; these days, people are tending more towards pan-firing, and steaming is not much advocated anymore. A Liu Bao tea-processing manual from this period contains this warning: "When carrying out the kill-green step, be aware of the following: It is important not to use the method of "soaking" (shui lao, 水潦) to achieve kill-green, because the active chemical compounds in the leaves can dissolve into the water, thereby greatly reducing the quality of the leaf." (Here, shui lao is a different name for the same lao shui technique). So, it appears that tea manufacturers of this period were already aware of the deficiencies of boiling and steaming as kill-green methods, and had begun to avoid them.

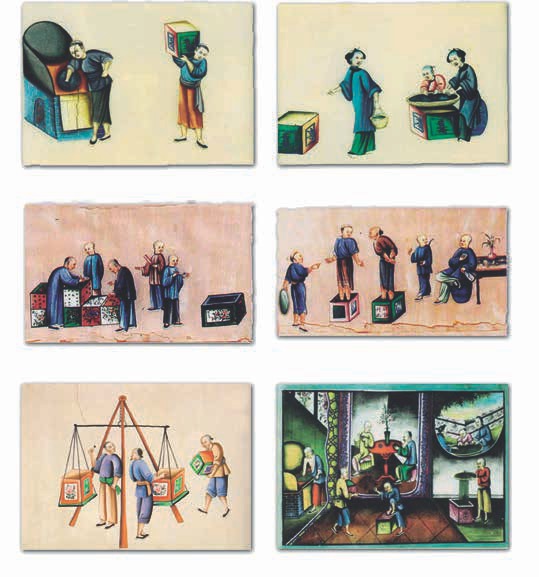

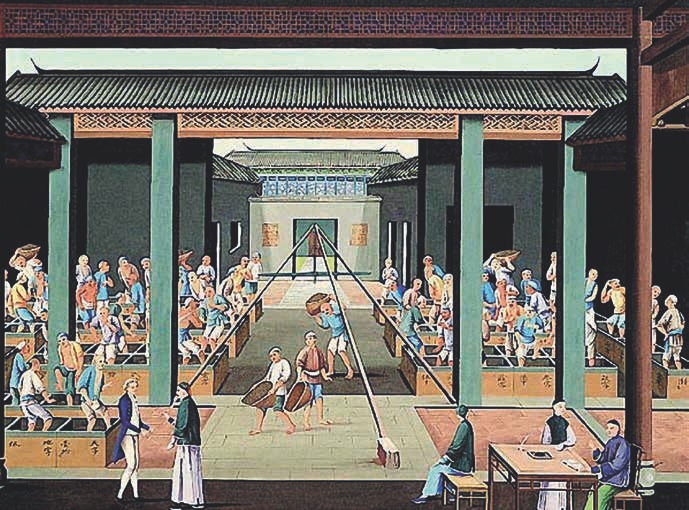

The image above is from a book entitled A Study of 19th Century Chinese Pith Paper Watercolors for Overseas Sale. The book contains a series of watercolor paintings on pith paper that portray the steps in the tea manufacturing process during the Qing Dynasty. Another set of illustrations entitled The Tea Workshop (below) depicts several tea-processing steps, including pan-firing, sorting, sifting, packaging the leaves and drinking the tea. This painting offers us an overview of the tea-making process and the associated tools during the Qing Dynasty. At the time, these watercolor paintings from Guangzhou depicting Chinese customs sold well in Europe and North America, and many have been preserved to present day. Several traditional processing methods have been passed down to modern times, from the mid-Qing to the period leading up to the Sino-Japanese War (which began in 1937). Traditional Liu Bao manufacturing methods continued to improve, giving rise to the six archetypal methods detailed below. ("Baking" here refers to the process of drying the leaves over a fire.)

This skillful process involves using rolls of sandpaper to determine the temperature and humidity level, and to carefully adapt the process to the weather conditions of the day, considering the temperature, humidity and whether the sky is clear or overcast. It requires the tea maker to work with the spirit of the weather and control the length of the process; there is even a special set of tea-making implements for this method. As for Grandma Tea, the processing methods are rather diverse and can involve either steaming or boiling (lao shui). Li Xuqiu once taught me his own method, developed through trial and error, for making Grandma Tea. The elderly Chajin told me that the steaming method used for the kill-green step in Grandma Tea could use some improvement, and should be done with special tools; he also invented his own unique steaming method. His method produced a unique tea that was very pleasant to drink, full of fragrance, with a strong, fresh, pure flavor. There are several 47/ Processing of Liu Bao Tea names in Chinese for the piling process, including ou dui (漚堆), wo dui (渥堆), yan dui (罨堆) and dui men (堆悶) - the latter is now generally considered standard. This process first began in the mid-Qing Dynasty when the Liu Bao tea production was on the rise, and large volumes of tea leaves were packed into baskets or heaped in a corner after being rolled, to await the next step: drying the leaves over a fire. The piling process gradually evolved from there and was passed down over time.

In rural tea workshops, the dui men process is carried out after rolling by heaping the leaves on wooden floorboards or in bamboo baskets. Young, tender leaves are generally piled to a height of 25 - 45 cm, while older, coarser leaves can reach 50 - 90 cm. Higher ambient temperatures call for a slightly thinner layer of tea, while colder conditions require thicker, taller piles. The piles of tea are generally left for around 16 - 36 hours, with shorter times for young leaves and longer times for old leaves. In addition, thicker piles require slightly shorter times, and thinner piles require longer. So, tea makers need to have a good grasp of these factors and adjust the process accordingly; they also need to turn the leaves over once or twice, judging by the degree of fermentation. If the temperature within the piles of tea reaches 55 °C, the leaves must be turned over immediately to dispel the heat; if the temperature drops to 30 °C, the tea must be gathered up into thicker heaps and left for an appropriate amount of time. During the initial drying phase, when the leaves are heated over a fire, the degree of drying is also important - when picking up a handful of tea, the leaves should easily form a ball without falling apart, but should not be damp to the touch. Then comes the re-moistening step, which must be carefully monitored; the leaves must be uniformly soft, so that gently squeezing a handful of leaves does not produce any crackling sounds. These days, the local tea farmers tend to use Method One from the list above for processing Liu Bao. Some techniques are passed down the generations as secret knowledge from the old tea masters and are not revealed to outsiders. After a certain amount of aging, the tea they produce becomes rich, strong and fragrant, and is sure to light up the eyes of any drinker. Despite this, some of the ancient tea-making techniques are already common knowledge in the area and are on the verge of disappearing.

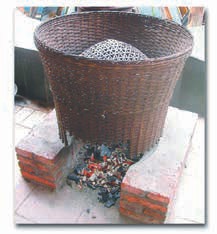

Bamboo is abundant in the Liu Bao region; this gave rise to the large woven bamboo baskets used for steaming Liu Bao. These baskets became a unique, convenient and affordable method of packaging the tea. But there were some drawbacks: each basket couldn't hold a large volume of tea, especially with medium-grade or coarser tea leaves; plus, the leaves tended to become crushed during shipping. This damage could be very costly, especially when the tea had to be transported long distances along the Old Tea Boat Road, all the way to Guangdong, Hong Kong, Macau and even Southeast Asia. To solve this, tea merchants invented a technique that involved compressing the leaves into baskets to air-dry after steaming them. Firstly, the merchants would sort the leaves they had purchased into four different grades, such as superior, fine, regular and coarse. (Other merchants used categories such as high grade, medium grade, and low grade.) Then they would pick out the yellow leaves, sift off the tea dust, steam the leaves to soften them and pack them into the baskets. Depending on the coarseness of the leaves, this technique allowed them to pack 2.5 - 5 times as much tea into the same-sized basket compared to before. This greatly reduced the space needed for shipping and eliminated the losses that resulted from crushed tea leaves. The tea merchants also quickly realized that packaging new Liu Bao tea in this way also made for a richer, mellower tea when aged; this steam compressing technique was established as a unique part of the Liu Bao tea manufacturing process.

As the technique evolved, variations were invented, such as the "twicesteamed, twice-dried" and the "many steamings, many dryings" methods. There are other names for these traditional methods, including "double-steaming" and "multi-steaming." In recent times, people have taken to using the phrase "twice-steamed, twice-sundried" as well - this one is incorrect, as Liu Bao tea has never been sundried. In the 1970s and 1980s, some local tea makers in Liu Bao still used the "many steamings, many dryings" technique as part of the Liu Bao refining process. An old "tea ticket" (an identifying label found inside each basket of tea) from Liu Bao tea's glory days (the late Qing to the early Republic, before the SinoJapanese War), contains a reference to this "steam processing" as an authentic part of Liu Bao manufacturing. In addition, the 1957 book Tea Picking and Processing Methods that we discussed earlier contains a direct reference to this method: "The tea factories steam it once more until it is soft and press it into baskets before transporting it to Guangzhou and Southeast Asia...because it is pressed into baskets before export, the name "Liu Bao tea" in the Guangzhou area refers to Liu Bao that is packed into baskets." In the section entitled "The Characteristics of Liu Bao Tea," the author mentions that "When the tea leaves are dry, they are a lustrous brownish-black in color; after being steamed and compressed into baskets, they are even blacker and glossier. When brewed, the liquor is a yellowish-red, and the leftover leaves turn a reddish-brown." Until the 1950s, the refining process for Liu Bao tea most often consisted of this steaming and compressing technique. Later, as the volume of tea for export rapidly increased, merchants would buy the unfinished maocha, sort and sift it, refine it using this steam compressing technique, and then send it off to places such as Guangzhou and Hong Kong to be repackaged. There, it would be marked with a brand name or divided into smaller packages before being sold in Southeast Asia.

"Hong Kong storehouses" are wellknown for their role in the history of Liu Bao tea. In their earliest form, they arose when tea merchants from Macau and Hong Kong set up premises in Liu Bao's Hekou Street to store their tea. For the most part, they bought dry tea leaves directly from the local tea farmers - in other words, the farmers processed the tea themselves from start to finish. With their sights on making a profit, the merchants were often quite picky about the local farmers' tea. The merchants from Hong Kong and Guangdong established their own set of tea-buying criteria to drive prices down; when it came to weighing the tea, they would pick out any yellow leaves first, and even take out their sieves and sift out some of the broken leaves and tea dust.

Faced with the merchants' demands, the tea farmers came up with their own method of "increasing" the weight of the tea, which was called "using the qi from the ground" or da di qi (打地氣). (Here, qi may carry a double meaning - that of "vital energy," which we may be familiar with, and also literally "steam"). The method involved carefully cleaning the floor and sprinkling it with water, then spreading out the heated tea leaves on the floor. The hot, dry tea leaves would absorb the water, which added a certain amount of weight. The farmers would then spread a layer of dry tea on top and take it to sell at the tea merchants' shops. Apparently, this method could add two to three jin in weight per hundred jin of tea (one jin is roughly equal to 500/600 grams).

Unsurprisingly, this practice was soon exposed. Some of the smaller tea merchants noticed that when they went to do business in Guangzhou, one hundred jin of tea always seemed to be short by a couple of jin by the time they wanted to on-sell it to merchants from Hong Kong or Southeast Asia! Gradually, these small traveling merchants also began to use this da di qi method themselves before re-selling the tea. Of course, this repeated adding of moisture had an impact on the quality of the tea. After a while, the Hong Kong tea merchants noticed that Liu Bao tea that had been repeatedly moistened in this fashion produced a rosy liquor, quickly lost its bitterness and astringency, and was even more popular than before.

Following market demand, Hong Kong's tea merchants slowly developed the practice of storing the tea in a humid environment - this was the earliest form of the so-called "Hong Kong storage" method. However, due to rapidly rising land prices in Hong Kong, the merchants had no hope of meeting market demand with the amount of tea they could process and store in their small basement workshops. So, the Hong Kong merchants spread this artificially sped-up post-fermentation method to Mainland China and began to establish large warehouses to emulate the "Hong Kong storage" method. In the 1940s and 1950s, Hong Kong merchants expressly used basement storage for Liu Bao tea, making use of the unique temperature and humidity conditions to artificially speed up post-fermentation. As the market continued to develop, the aged fragrance and red liquor of puerh and Liu Bao tea gained wide acceptance among consumers. In Hong Kong's tea houses during this period, puerh and Liu Bao together accounted for over 80% of tea consumption.

According to a record in the Guangxi Agricultural Dispatch from 1945, "After Liu Bao tea is harvested, Cantonese merchants set up shop at Hekou to purchase the tea. They then boil the leaves again to make them into tea cakes. The result is very fine, and when boiled and drunk, the flavor is similar to puerh tea. Around five hundred thousand jin of these are produced each year" (this is equivalent to 250 metric tons). The reference to "boiling" the leaves to make into tea cakes actually means steaming the leaves to soften them, then using a wooden mold to form them into discshaped cakes. The praise given here for these "very fine" tea cakes is in keeping with the recollections of the elderly Chajin who remember this period, and confirms that the art of making tea cakes had already reached a certain maturity. From the statement that "the flavor is similar to puerh tea," we can infer that there was some confusion among people of the time regarding the original leaf and manufacturing techniques used for these two types of tea cake.

According to research, the merchants who established themselves at Hekou in Liu Bao during this period would sometimes use the leaf from the Liu Bao tea plant varietal to make puerh tea, to cater to a different niche in the market. In the late Qing Dynasty, at the same time that loose-leaf Liu Bao tea was available, there were also other types, such as tea discs, or bing (餅), tea bricks, Liu An tea in bamboo baskets, and Hua Juan ("Flower Roll") tea, which was wrapped in tubeshaped bamboo packaging. (There's a similar type of tea from Hunan called Anhua Qianliang, or "Thousand Tael" tea). These compressed shapes created a greater diversity of different tea products, and also reduced the space needed to transport the tea, thus lowering costs. All of these shapes required the tea to be steamed first to soften it for compression.

According to the recollections of Chen Yongchang (陳永昌) from the Xing Sheng Tea Shop, the shop used to hire several strapping fellows to trample the tea and to pull the bamboo strips, to tightly wrap the Flower Roll tea; then they would place the tubeshaped tea rolls in the corridors to airdry. They had to steam the tea quite thoroughly before they could make those Flower Rolls. Chen Yongchang recalls that at the time, he didn't know there was also a similar method of tea packaging in Hunan. Mr. Li Xuqiu, the Chajin from Liu Bao in his nineties, also recalled how "the tea cakes we made at that time were round, like a compass." The exact implement he refers to is a luogeng (羅庚), a traditional Chinese compass. He also described the round tea cakes they used to make in careful detail: they were beautiful and finely made, similar in shape to today's tea cakes.

As we saw earlier, the initial phase of processing generally includes killgreen, first rolling, piling, second rolling and drying. The refining process includes "filtering" (sifting the tea and picking out stems and debris), blending, first steaming, piling, second steaming, compressing into baskets and air-drying (for at least half a year). The particular piling method used in the refining phase is known as ju dui (焗堆), and is a key part of the Liu Bao manufacturing process. It was an early technique that improved over time; it had its origins in the early practice of compressing the tea into baskets, and evolved into a specific step in the refining process. Its goal is to induce fermentation under the influence of water and heat, causing some of the phenolic compounds in the tea to oxidize, and resulting in a brownishyellow or red leaf and a bright redorange liquor with a mellow and harmonious flavor. Ju dui techniques have varied over the years: In its earliest form, the method involved observing the tea leaves after blending them and deciding whether to add water, based on the existing moisture level, then tossing the leaves to mix evenly before putting them in the steamer. The steaming time varied from around 1 to 2.5 minutes, depending on the tea: young, tender, high-grade leaves would need less time, while older, coarser, lowgrade leaves would need longer. The leaves were ready when they were uniformly soft and moist, and could be squeezed into a ball without falling apart when released. To carry out this ju dui step, the manufacturers used special "piling beds," a wooden platform with an area of around 50 square meters, surrounded by wooden sides made from China fir, about 60 centimeters high. Each bed could contain 5 - 8 tons of tea. The leaves were generally left in these piles for 6 - 10 hours. If the temperature was higher and the leaves on the younger side, the piles would be tossed every five hours to dissipate the heat and make sure the leaves fermented evenly. In later times, ju dui techniques progressed, and many places now have specialized steaming machines that use a boiler to steam the tea. The temperature must be checked often to make sure the tea remains unblemished by mold or rot. (For more details on how the conditions are regulated in this ju dui process, see the information under "First Steaming and Piling," in the section on "Refining" later in this article.)

According to records, the Wuzhou Tea Factory used this ju dui technique in their Liu Bao tea refining process in the early days. In the beginning, Liu Bao tea was only piled to a height of 1 m (with coarse tea) for the initial steaming and ju dui process. This turned out not to be thick enough, as it allowed the steam to dissipate, so the tea was often under-fermented, resulting in an insufficiently red liquor and a lingering bitter, astringent flavor. From 1956 onwards, the Wuzhou Tea Factory began to improve this method, heaping the coarser tea to a height of about 1.5 m. The tea makers would add the batches of steamed tea layer by layer to make a tall stack, compacting each layer as they went, while making sure the pile didn't become too solid in the middle. They would sprinkle water on the floor of the area to make sure the tea on the bottom layer was sufficiently moist. Once the pile was complete, they would surround it with boards of China firwood to form "walls." They would then lay a wet straw mat on top of the pile and weigh it down with wooden boards. After about 24 hours, the tea could proceed to the second steaming. This solved the problem of insufficient or uneven fermentation.

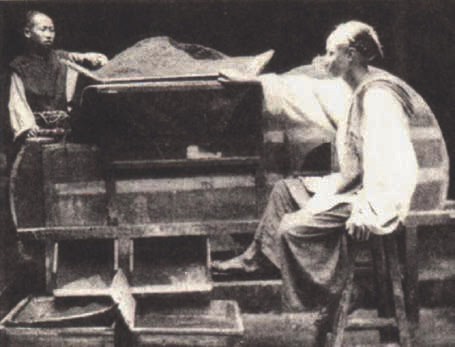

Originally, the rolling step that came after kill-green in Liu Bao manufacturing was done by hand, and later, by trampling the tea leaves with the feet. But as production volumes increased, tea makers began using wooden machines to roll the tea. Liu Bao locals call these "tea grinders." They looked and functioned a bit like a hand-operated mill. Later, water-powered versions were invented, which were even more efficient. However, the process and equipment for the following step, drying the leaves, didn't advance much. Originally, the leaves were dried in small batches in a pan on a stovetop, so the tea maker could roll them as they heated. Many of Liu Bao's elderly Chajin recalled that as production increased, the speed of the drying process couldn't keep up with demand. The output of one drying pan after 3 - 5 hours was a mere couple of kilograms of tea; in one evening, one stove could produce a little over 5 kilograms of tea at most. It was impossible to keep up with the speed at which the tea was being rolled - one batch of tea took around 1 - 2 hours to dry. This meant that large amounts of rolled tea had to be left sitting in heaps, waiting to be dried.

From the mid-Qing Dynasty, especially from 1895 onwards, the demand for Liu Bao tea grew rapidly, and plantation areas were constantly expanding. During the tea-making season, the farmers would pick the tea during the daytime and carry out the kill-green and rolling steps at dusk. When evening rolled around, there wasn't enough time left to complete the drying phase, so they had to make do with stopping when the tea leaves were around 70% dry and continuing to dry them the next morning. Later on, some of the larger and wealthier tea producers were outputting more than 100 kg of tea per day, and at that point, there wasn't even enough time to dry all the leaves to 70% on the same day - they had to simply pile the rolled tea into a corner and wait until the next day to dry it in batches. The tea farmers and merchants very quickly noticed that leaves which had been piled like this for 10 or so hours produced a mellower, richer flavored tea, with much less astringency and bitterness, which became more popular with drinkers. From then on, this method of piling the tea overnight before drying it became an established part of Liu Bao manufacturing. This early-stage piling process became known by locals as yan dui (罨堆). So, this ancient technique of piling the tea to ferment in its own juices can be verified by the recollections of Liu Bao's older generations of Chajin.

The earliest record I was able to find was in the Guangxi Province Supply and Marketing Cooperative's Tea Picking and Processing Methods, published in June of 1957. The book contains a clear reference to this piling method: "Liu Bao tea was originally produced in Liu Bao Village in Cangwu County. The manufacturing process is rather unique: It is not green tea, nor is it red tea, and it is unique to this province; therefore, it is named 'Liu Bao tea' after its place of origin. Its most notable characteristic is that after kill-green and rolling, it is heaped for several hours to implement post-fermentation before being dried..." In the same book, it is also stated that "The fermentation process is similar to that used for red tea, though red tea is fermented before pan-firing... Liu Bao tea is fired first then fermented, and the fermentation time is relatively long... so, it is called 'post-fermented' tea." The records in this publication also clearly establish "piling to ferment" as a step in the manufacturing process: "The fermentation method is as follows: After the leaves are rolled and separated, they are spread out on a winnowing basket or bamboo mat to a thickness of around three to four inches, and are left to naturally ferment. After they are left overnight for around six or seven hours, the leaves change color from fresh green to a greenish-yellow..." So, we can see that at the time, "post-fermentation" was already an established technique and was being promoted via this official publication.

From this book, we can confirm that this "post-fermentation" technique was used in Liu Bao processing well before it began to be used for shou puerh in 1974. A textbook from the National Agricultural Secondary School entitled The Study of Tea Making, contains a description of piling as part of the initial Liu Bao processing phase (the textbook uses the term wo dui): "This process uses the effects of heat and moisture to break down the chlorophyll and accelerate chemical changes within the leaves. This reduces bitterness and astringency, deepens the color of the tea liquor, makes the flavor richer and changes the color of leaves once brewed... During piling, the thickness of the tea piles depends on the air temperature, the humidity and the age of the leaves; generally, the piles are 30 - 50 cm thick. If wicker baskets are used, each basket can contain around 20 kg of damp tea. High temperatures or young, tender leaves call for a thinly spread layer, while old, coarse leaves should be packed tightly into thick piles. The tea leaves are turned over once or twice during piling, with the leaves nearest the outside being moved toward the center to promote even transformation. The total piling time varies from around 10 - 15 hours, depending on factors such as the age of the leaves, the air temperature and the weather. In general, low temperatures, rainy weather and old leaves require a longer time, while the opposite conditions require a shorter time." From these records, we can observe two variations on the traditional method: piling the tea into baskets or simply piling it in the corner of a room. The method described here was the earliest precursor to the process of piling to achieve post-fermentation. So, we can also see that the three different names for this post-fermentation piling phase - ju dui (焗堆), ou dui ( 漚堆) and wo dui (渥堆) - do refer to slightly different techniques that have taken different paths in their evolution.

Even though in later times Chajin began to confuse the terms ou dui and wo dui and even used them interchangeably, there is a difference in terms of the exact technique. The ju dui method involves first steaming the maocha to add heat and moisture before carrying out the post-fermentation process. It evolved from the practice of steaming the tea and compressing into baskets, the so-called "many steamings, many dryings" technique that we discussed earlier. It is characterized by the fact that steaming adds both heat and moisture, but not a large volume of water. In the Liu Bao tea region, the term ou dui (沤堆) refers to what is locally called yan dui (罨堆). The word yan means "covered," or "sealed," so it indicates that the piles of tea are covered up and left to ferment in an enclosed space. Another term with the same meaning is dui men (堆悶), with men also meaning "sealed" or "covered" and dui simply meaning "pile." In Cantonese, the character "沤" (Mandarin pronunciation: ou) carries the meaning "to steep for a long time" and also "to pile up." So, the local meaning of ou dui is to cover the tea leaves with a bamboo mat after rolling and let them ferment in their own juices, without adding water. The term was originally used to refer to the fermentation that occurs in the initial processing phase, as opposed to the refining phase. (This method is also quite different to the men huang and men dui processes used for yellow tea, in terms of the time, temperature, water content and speed of the chemical and physical changes.) The character 渥 (wo) means "to moisten," so it implies the involvement of water. Thus, the term wo dui (渥堆) was originally exclusively applied to the more recently developed method of adding water to aid fermentation, which is a step in the second phase of Liu Bao processing: the refining phase.

This method requires sprinkling a sufficient amount of water onto the tea piles to promote fermentation. So, as we can see, the wo dui and ou dui methods are quite different in terms of the height of the tea piles, the piling time and the techniques used. But since the details of these two methods are not widely known, the terms wo dui and ou dui have become confused, and today are used interchangeably to refer to the piling process, even in specialized tea publications. In addition, many publications use the same term (be it wo dui or ou dui) to refer to the piling step that happens in the initial processing phase of Liu Bao as well as the piling step in the refining phase. These two piling steps are different and should not be confused. The piling step in the initial processing phase is more correctly referred to as dui men. This dui men step (formerly called ou dui) is unique to the initial processing phase of Liu Bao - puerh tea processing does not have an equivalent step. Professional publications have also lacked discussions of the differences between the dui men step of initial Liu Bao processing and the wo dui step in the refining process, in terms of technique, temperature, humidity, time and chemical/physical changes. So, over time, the distinction between these two has also largely become blurred.

As we've seen, the modern Liu Bao manufacturing process can be split into two main phases: initial processing, or chu zhi (初制), and refining, or jing zhi (精製). In the following pages, we will explore both of these stages in much greater depth, hopefully leaving you with a feeling that you understand and appreciate the richness of Liu Bao production.

The initial process of making the maocha, or semi-finished tea, includes the following five steps:

This step halts oxidation in the leaves. Around 3 - 4 kg of tea leaves are placed into a large wok at a temperature of between 90 - 120 °C. Older leaves are packed more tightly, while young, tender leaves are spread more loosely. The leaves are ready when they become fragrant and soft, change from bright green to dark green, lose their shine and begin sticking together. At this point, they are taken out for rolling. The kill-green process takes about 5 - 6 minutes in total.

The goal of rolling is to shape the tea leaves and also to damage the leaf cells. The aim is to achieve about 60 - 65% damage to the cellular tissue in the leaves. It's important to avoid rolling the leaves heavily for too long. The best approach is to first knead them lightly for about 5 minutes; then, when the leaves begin to roll up into thin strips, they can be rolled with more pressure for another 15 minutes, then lightly again for another 5 minutes. Then, after sifting, the leaves should be rolled for another 10 - 15 minutes. The whole rolling process takes 40 minutes for first- and second-grade tea, and 45 - 50 minutes for third-grade and below.

This is a key step in the processing of Liu Bao. There are two possible techniques for this: the bamboo basket method and the bamboo mat method. The first method involves filling a bamboo basket with 20 - 25 kg of tea. The second involves piling the rolled leaves to a depth of 30 - 50 cm on top of a bamboo mat, then covering the pile with a wet cloth or sackcloth and leaving it for 10 - 15 minutes. During this time, the leaves must be tossed 2 - 3 times to mix them evenly. The most important part of the dui men process is to maintain the temperature of the tea piles at around 50 °C. If the temperature reaches 55 - 60 °C, the piles must be repeatedly stirred up to ensure an even temperature and prevent the leaves from turning black. This continues until the leaves have turned from dark green to a brassy color, and until their pungent, vegetal scent transforms into a sweet, mellow fragrance. The overall time usually ranges from 20 - 30 hours, depending on the age of the leaves, the air temperature and the thickness of the piles. One common traditional method is to lay a cloth over the tea piles and leave them overnight until early the next morning.

High-grade teas generally don't need to be rolled again and can be dried directly after piling, but these days, most methods include a second rolling. This has the benefit of re-curling any leaves that have unfurled during the piling phase, and of ensuring a uniform moisture content, which helps the leaves dry efficiently afterwards. Before the second rolling, it's advisable to bake the leaves at a low temperature of 50 - 60 °C for 7 - 10 minutes, then lightly roll them for 5 - 6 minutes, until all the leaves are once more tightly curled into thin strips.

The tea is dried over a wood-fired stove. The drying phase is usually divided into two parts: initial drying and thorough drying. For the first step, the leaves are spread around 3 cm thick and dried at a heat of 70 - 90 °C, stirring every 5 minutes or so. Once the leaves are 60 - 70% dry, they are spread out and set aside for an hour to allow the water content to evenly redistribute. They are then ready for the "thorough drying" step, where they are spread out to a thickness of 5 - 6 cm and slow-baked for a long time at 50 - 60 °C. When drying Liu Bao, sun-drying cannot be substituted for drying the tea over a fire. It was traditional to use pinewood, though personally, I think it's preferable to use a wood that, unlike pine, doesn't produce a strong-smelling smoke and influence the flavor of the tea. When stirring the tea, it's important to do so lightly, to avoid burning the leaves. The tea should be dried until the leaves can be crumbled into powder with the fingers and the tea stems snap easily when bent. This will make the best and brightest tea liqour with a full body and rich flavor and aroma.

Next comes the refining process: after the leaves are graded and any yellow leaves, stalks, and so forth are picked out, the tea is filtered and graded, blended, steamed once for piling, steamed again for compressing into baskets, and finally air-dried and packaged for sale. Liu Bao tea is sorted into five grades, depending on the age and thickness of the leaves (in the past there were also three other grades). Sometimes the tea will be sifted and blended, depending on the quantity and the quality of the leaf. Occasionally, the manufacturers will even blend tea from different batches of maocha together to improve the flavor. The initial steaming and piling step is crucial, using heat to change the chemical composition of the tea, to change the color of the leaf to reddish-brown and the tea liquor to a deep red with a rich, mellow flavor.

High-grade tea requires less steaming time, while coarse, lower-grade tea needs a bit longer. The leaves are steamed until they're soft and moist, and remain stuck together when balled up in a fist. They are usually steamed using a boiler for 1 - 1.5 minutes. After steaming, the tea is laid out to cool down to around 80 °C, when it is ready for the dui men piling step. The depth of the piles depends on the age and coarseness of the leaves: firstto third-grade tea is piled to between 60 - 80 cm, while grades four and five are piled to a height of 1 - 1.5 m. Firstand second-grade tea need to be compressed from all sides of the pile, with a bamboo mat or similar cover laid on top, while third- to fifth-grade tea piles must be compacted around the edges while left loose in the center. Once the piling commences, the windows and doors of the fermentation room must be sealed tightly. The tea piles must be turned over once during piling, generally after 7 - 8 days, once the temperature of the tea piles has reached 50 - 60 °C. Once the tea is suitably fermented, the leaves will be soft and yellowish-brown or reddish-brown in color, and will give off a rich, fragrant aroma. The entire process usually takes 15 - 20 days. Throughout the process, the temperature of the piles should remain at around 50 °C, and the humidity should be around 85 - 90%. The water content of the leaves should remain around 18 - 20%.

This process has its roots in the traditional method of steaming the tea to compress it into baskets. However, the equipment used for this step has evolved a lot: these days, the steaming is usually done with a boiler or a specialized steaming machine, hence the two-part steaming process. Because of this, the whole refining process is sometimes referred to as the "double-steaming" process. The steaming machines usually consist of a round metal plate with a three-layered frame inside to hold the tea leaves, and steam holes in the bottom. Each layer is filled with about 20 kg of tea leaves, which are then steamed at 100 °C until the leaves are thoroughly damp and hold together for a while when squeezed into a ball. Around 4 - 5 minutes is usually long enough for first- and second-grade tea, while third- to fifth-grade tea may take 6 - 7 minutes. Steaming the leaves for too long should be avoided - if the water content gets too high it can affect the quality of the tea.

Once the tea is fully steamed, the round steaming plate can be turned to unload the three layers of tea into large bamboo baskets, compressing each layer tightly after it's added. Each basket contains around 60 kg of tea. Ideally, the tea will be tightly packed around the outside and a bit looser in the middle. After this second steaming, the baskets of tea are placed in a cool, dark, well-ventilated storage area so that the tea can cool down and the remaining moisture can evaporate. After 6 or 7 days, once the tea has cooled to room temperature, the baskets are sealed up and transferred to a storage warehouse. The warehouse needs to be cool and dark, with a humidity of around 85%. The baskets of tea are stacked neatly on wooden racks, and the storehouse is sealed up. After two months, the windows are opened to aerate the storeroom, dispelling any odor and allowing the water content of the tea to further decrease. After another six months of storage, the tea matures into finished Liu Bao, with a red-colored liquor.

The Liu Bao refining process in the early days of the Wuzhou Tea Factory was as follows:

Filtering and picking out debris → Blending → First steaming → Piling (ju dui) → Dismantling the piles → Laying the tea out to dry → Second steaming → Compressing into baskets → Aging in storage

At that time, Liu Bao tea was classified into grades from one to five, plus "un-graded" tea. The ju dui piling method was standard for carrying out post-fermentation. According to records, in 1954, the Wuzhou Tea Factory made some improvements to their methods of filtering the tea and removing detritus, while also improving their tea-steaming cauldrons and acquiring some more, and increasing the thickness of the piles as well as their ju dui technique.

In the late 1950s and early 1960s, Liu Bao tea saw a boom in popularity in Southeast Asian export market, and the market in Hong Kong and Southeast Asia became flooded with Liu Bao tea made from tea leaves from Vietnam, Thailand, Myanmar and Malaysia. This posed a serious threat to the production and export of authentic Liu Bao tea from Guangxi. According to the recollections of elderly Chajin Guo Weichen (郭維琛), the export market for genuine Liu Bao did suffer from the influence of this "Liu Bao" tea made from other types of tea leaf.

1946 saw the founding of the Hong Kong Tak Son Hong Company (which belonged to the Hong Kong China Resources Company). From 1949 onwards, this company became the head representative of all companies importing and exporting local products from Mainland China to Hong Kong and Southeast Asia. They traded in tea and other goods, and became quite well-known in Hong Kong tea circles. The Hong Kong Tak Son Hong Company was intimately involved in the development of the technique of piling to ferment the tea in Guangxi and Guangdong, before it first appeared in Yunnan. According to the recollections of the older generations of Chajin, from the early 1940s through to the 1950s, market demand saw more and more Hong Kong merchants producing this imitation Liu Bao, which led to the development of a quite robust piling technique. There were quite a few companies making this tea, known on the streets as "red flood tea," including Sang Kee, Baotai, Lian Xing Long and Changzhou Fuhua. Early on, merchants from Hong Kong and the southern provinces realized that storing teas such as Liu Bao and puerh in an environment with high humidity and a constant temperature could speed up the aging process. In Liu Bao's tea villages, too, purveyors of tea noticed early on that high humidity could promote faster aging.

From 1946, the rapid rise of Hong Kong's land value led some merchants to store tea in cellars or storehouses built into hillsides, and they noticed that the tea matured quickly in these conditions. This process was still fairly time-consuming, taking one to two years, and required access to a cave dug into a hillside - so, of course, this method was not available to all tea merchants. So, some merchants tried to imitate these hillside storage conditions by spraying tea with water and packing it into hemp sacks for storage. They soon realized this was also quite effective, and through experimentation, they developed a process that included steps such as regularly checking the sacks of tea, turning them, ventilating the area and dissipating the heat. Through keeping careful track of the changes in the leaf, they determined the optimal storage time. After about a year, or even six months, the tea would develop its characteristic red liquor, rich flavor and "aged" fragrance. Thus, they arrived at a method that was both simpler and faster. Even better was that after they got used to the taste, consumers began to favor this "aged tea."

This type of artificially aged Liu Bao and puerh were quite popular among consumers, and aged tea began to gain a following. Thanks to this, large quantities of this "aged tea" were sold locally in Hong Kong and exported to various Southeast Asian countries under the name of "Liu Bao" tea. Because of its low-cost source leaf and short processing time, this "red flood tea" had a significant impact on the export market for Liu Bao tea from Guangxi and Guangdong. Although at the time, there wasn't a lot of close contact between Hong Kong and the Mainland, there was certainly still a flow of information between these southern Cantonese-speaking regions, particulary between local Guangxi and Guangdong enterprises and re-export companies such as Hong Kong's Tak Son Hong. In response to the threat from this "red flood tea," Tak Son Hong reported the situation back to the tea growers in Guangdong and Wuzhou, and brought back samples of the tea for local producers to study.

The Guangdong Tea Import and Export Company sent a team specifically to gather information about the Hong Kong merchants' techniques of using green tea maocha and artificially aging and fermenting it. They collated, compared and analyzed all the different techniques used for making "red flood tea," and developed a set of procedures for the wo dui piling technique. They then conducted a series of post-fermentation experiments at the Da Chong Kou Tea Factory in Fang Village, which was affiliated with the Guangdong Tea Import and Export Company. According to records from Guangdong, after two years of experimentation, they finally achieved success in the spring and summer of 1957. At around the same time as this process in Guangdong was beginning, the Wuzhou Tea Factory also began researching post-fermentation techniques, using the information and samples provided by Tak Son Hong. According to Wuzhou Tea Factory's senior technician Qin Jiquan (覃紀全), in 1958, the Fuzhou Tea Factory succeeded in developing the modern Liu Bao wo dui piling technique, and began to commercially produce some of their tea using this method.

However, it wasn't until 1965 that all the tea was produced using the modern method. That year is considered to mark the official appearance of modern Liu Bao tea. Existing records indicate that in 1873, a small group of experts from Yunnan's tea factories was sent to the Guangdong Tea Import and Export Company to study puerh tea production techniques. The group included Zou Bingliang (鄒炳良) from the Hai Tea Factory, Wu Qiying (吳啓英) from the Kunming Tea Factory and Cao Zhenxing (曹振興) from the Xiaguan Tea Factory. As a result, Yunnan tea producers also started using the wo dui post-fermentation technique for puerh tea, and began large-scale production using this method. In terms of the raw leaf, from 1954, privately owned tea businesses were forbidden from purchasing maocha (the "raw," or really semi-processed, leaf ), so most of the Liu Bao leaves grown in Guangxi were bought by the state-operated Supply and Marketing Department, with uniform prices and tea grade standards set by the state. The tea from the region was then all sent to the Wuzhou Tea Factory for refining and eventually export.

Around the same time, the staterun Heng County Tea Factory was established. 1966 saw the establishment of another state-run factory, the Guilin Tea Factory. The semi-processed maocha from the surrounding regions was also sent to these factories for refining and preparation for export. At this time, significant changes began to emerge in the Liu Bao maocha. The Guilin Tea Factory mostly used tea leaf varieties, such as Linggui large-leaf, Longsheng Longji, Xing'an Liudong and Lipu Xiuren. The Wuzhou Tea Factory, on the other hand, mostly used leaves from the local population of Liu Bao varietal tea plants. Gradually, other leaf varietals, such as Shanglin Antang, also came to be used for producing Liu Bao tea. Later on, there appeared another variety familiar to many Chajin, the Gui Qing tea varietal, which was also used to make Liu Bao. At the time, local tea factories in Liu Bao were using cold fermentation techniques. Then, in January of 1953, the Guangzhou branch of the China National Tea Corporation set up an office in Wuzhou. This spurred technical progress in the local tea factories, and they began using the modern wo dui post-fermentation technique to make Liu Bao. The Liu Bao that was exported gradually came to be produced using this method.

In 1976 in Cangwu County, the Liu Bao Village Chujing United Tea Processing Plant was founded. From its founding until May of 1979, this factory still used traditional Liu Bao refining techniques, such as the "double-steamed," "multi-steamed" and ju dui (piling) methods. According to a record from materials produced by the Cangwu County Local Product Corporation's Tea Group, from May 1979 to October of 1982, Cangwu's Liu Bao tea producers began using the modern wo dui cold fermentation technique in their refining process. The materials state that "The current production cycle of Liu Bao tea is lengthy and unable to satisfy market demand; the cost is also relatively high. Because of this, Liu Bao tea production methods are being reformed." From then on, almost all large-scale producers of Liu Bao used the modern method, with the wo dui "cold fermentation" piling technique replacing the earlier ju dui (sealed piling) technique in the refining process. The Liu Bao refining process includes the following steps:

Sifting and filtering → Blending → Piling (wo dui) → Steaming → Compressing and shaping → Air-drying and aging

The wo dui piling technique is a crucial part of the Liu Bao manufacturing process, and retains an air of mystery - the exact details are kept a closely guarded secret by those in the industry. The workshops where piling takes place are considered a restricted area, with controlled entry and no visitor access. Nevertheless, during my interviews with many of the older generations of tea masters and Chajin, they shared some knowledge about the wo dui process, and in some cases the culmination of decades of personal experience. So, now I may share some of this knowledge with you, the reader. The wo dui process involves artificially accelerated post-fermentation, according to the following steps:

Sifting → Picking out stalks and debris → Blending → Piling up the leaves → Adding water and fermenting → Turning over the piles → Fermenting again → Turning over again (the steps of turning over the leaves, breaking up clumps and adding water are repeated multiple times)

It's critical to regulate the depth, water content and internal temperature of the tea piles. The water content in the leaves needs to be between 25 - 30%, and the piles are between 50 cm and 1 m deep, depending on the grade of the leaf. The temperature should be kept between 45 - 60 °C. If the temperature creeps toward the higher end of the range, the tea piles must be promptly turned over to ensure the tea ferments evenly at the bottom and on the surface of the heaps. Any clumps must be loosened up - this is usually done with a special machine.

Experienced tea masters can distinguish the moisture content and degree of fermentation just by picking up the leaves, holding and rolling and smelling them. They can feel the temperature and moisture content with their hands, without needing any implements, and know what steps to take, depending on the changes in temperature. One of the old Chajin I spoke to emphasized the importance of water content during piling. The key to adding water is to understand how to observe the tea and adapt your method accordingly. High-grade tea, for example, needs less water, and lower grade tea with coarse and sometimes also tightly-rolled leaves requires much more water to aid in fermentation. It's also crucial to sprinkle the water evenly across the tea piles; you mustn't just pour it on and risk flooding the bottom of the heap. When the water content is just right, the tea leaves do not make a rustling sound when you pick up a handful; once you loosen your grip, the leaves do not ball up, but separate slowly and naturally fall to the ground one by one, without sticking to the hand. The palm of your hand may remain a little damp once the leaves fall, but it shouldn't be noticeably wet, and certainly not dripping. Judging the temperature of the tea piles is also important, to avoid "cooking" them with overly high temperatures. However, these days, most people string up a couple of rows of thermometers above the tea piles, so they can easily be stuck in to monitor the temperature, particulary in the heart of the piles.

Regarding Yunnan puerh, we can find some useful information in an article called Puerh Tea: Yunnan Shou Tea penned by the president of the Yunnan Tea Association, Zou Jiaju (鄒家駒). The article begins by stating that "As everyone knows, Yunnan began producing shou tea in 1973." The author continues: "I have consulted literary and historical sources from the regions associated with producing compressed tea cakes, namely Dali, Ban'na and Simao, and there is no record of shou tea being produced prior to 1973... Before 1948, compressed tea was the only type to be exported to Hong Kong from Yunnan. From the early 1950s onwards, however, most of the Yunnan tea arriving in Hong Kong was loose-leaf tea." I was able to confirm with Hong Kong's tea merchants and industry insiders that in the 1950s, owing to Liu Bao tea's surging popularity, a certain amount of loose-leaf Yunnan puerh was exported to Malaysia labeled as "loose-leaf Liu Bao" tea. For a few years on either side of 1949, there was a trend for this type of looseleaf, basket-packaged Liu Bao in the Cantonese regions of southern China, Hong Kong, Macau and Southeast Asia.

In the '50s, loose-leaf Yunnan puerh was also big in the market. During this time, Hong Kong merchants noticed consumers' warm reception of the mellow, fragrant Liu Bao that had been aged by piling, and began to store Liu Bao and puerh in basement storehouses, making use of the unique temperature and humidity to promote artificial post-fermentation. As the market continued to evolve into the late 1950s, Hong Kong teahouses mainly served this "red flood tea," and tea drinkers came to prefer this "ripened" tea with its aged fragrance, red liquor and brown leaves. In his book, Mr. Zou Jiaju also recounts that "In the '50s, there was almost no communication between Hong Kong and the Mainland, but news of Hong Kong's artificially post-fermented tea still got through. On November 2nd, 1955, the (Yunnan) provincial corporation instructed the Xiaguan Tea Factory to start experimenting with post-fermentation on their compressed tea for export. Due to a lack of information, the experiments were inconclusive."

In 1974, after many years of further study and experimentation, they finally succeeded in producing "ripened" shou puerh tea using post-fermentation. In reality, of course, Liu Bao tea had been produced using post-fermentation techniques since before the Sino-Japanese War up until 1953, using the traditional "double-steaming," "multi-steaming" and ju dui sealed piling methods. In 1958, as we've discussed, the Wuzhou Tea Factory invented the modern wo dui technique for post-fermenting Liu Bao, and in 1965, this method began to be replicated en masse. According to one of the elderly workers from the Wuzhou Tea Factory, in the early 1970s, some fellow tea professionals came to the factory from Yunnan to study the use of post-fermentation techniques for making shou puerh tea. It's not clear whether they ended up applying the wo dui piling technique borrowed from Liu Bao tea in their own tea production.

Storing the tea to dry and age it is the final key step in the Liu Bao production process. The storage method is very important: After the final steaming and being packed into baskets, the tea must be placed in a clean, cool, dark, well-ventilated and odor-free environment. Once the tea has cooled to room temperature and the water content of the leaves have dropped below 18%, the tea is transferred to a new storage area to age. The conditions must be clean, with a humidity of 75 - 90% and a temperature between 23 - 28 °C, and again, an absence of odors. Later, it is moved again to a clean, cool, dark, dry, odor-free wooden storehouse to finish maturing. The entire aging process wouldn't normally last more than 180 days. An alternative method is to use warehouse-style storage to complete the aging process: The baskets of tea are stacked in rows in a cool, dark warehouse, resting on wooden boards - the baskets of tea must not be placed directly on the ground. The warehouse should then be sealed up, and be maintained at a humidity of 75 - 90%. After about 60 days, once the liquor has attained the desired color, the windows and doors are opened up to ventilate the warehouse and gradually decrease the moisture content in the tea.

The drying and aging process has some very specific requirements as to the method and environmental conditions. There's an interesting story related to this: during the planned economy era prior to the 1980s, the Huang County Tea Factory and the Guilin Tea Factory tried their hand at producing Liu Bao Tea, but because the weather conditions in their respective regions were so different from the conditions in Wuzhou, the quality and flavor of the tea they produced was not nearly as good. As a result, many of the teas produced by the Guilin Tea Factory were actually sent to Wuzhou for "re-aging" before being exported along with Wuzhou's own tea!

In 2002, the Guangxi Inspection and Quarantine Bureau released an industry standard for Liu Bao tea (titled Liu Bao Tea GXCIQ88-2003). The standard was developed in cooperation with the Wuzhou Tea Factory and the Wuzhou Tea Import and Export Corporation, which were the only two enterprises producing Liu Bao at that time, and was based on the practices used at these factories. The standard was put into practice on October 8th, 2003, and marked the beginning of an era of standardized Liu Bao production with uniform technical specifications. Then, on May 27th, 2009, the Guangxi Zhuang Autonomous region also released a regional standard (DB45/T581-2009 Liu Bao Tea), which was implemented on July 30th of the same year. This standard contained unified specifications for aspects of Liu Bao tea production, including definitions and terminology, classification and grading, testing methods, inspection regulations, branding, packaging, transportation and storage.